Can a mouthpiece 3d printed on a home machine and created from a file found on the internet actually be playable? The short answer is a remarkable, maybe! As you might imagine there are quite a few caveats to print and play sax mouthpieces and I’ll touch on those shortly.

Background:

I’ve been heavily into 3d printing for a few years. From building my own machines to ready to print machines, I’ve been involved in the community. I toyed with the idea of 3D printing a sax mouthpiece but my design skill limitations made that an unlikely possibility unless someone else made the design. then a few years ago i learned of students at the TU Delft were using acoustic principles, 3D printing and professional saxophonists to test designs. I was enamored that this was being pursued in a serious and researched way. I suspect that it was some of these students that would go on to form the saxophone mouthpiece company SYOS.

After a few years I had forgotten about 3D printing a mouthpiece until Mark at 10MFan mouthpieces released his then new models Robusto and Merlot as 3D printed versions. They were made of a metal rich material and quite heavy. The were hand finished by Eric Falcon. I purchased 1 of each the instant he said I could. They are smooth, heavy and play precisely like their machined from hard rubber cousins. This drove me back to the search for a 3D printable baritone mouthpiece and i finally found something that looked like it would work.

Mouthpiece:

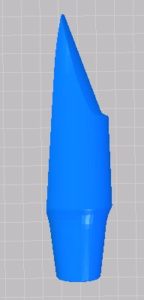

From first glance this piece should be quite easy to recognize. If you have play classical music in school then this rendering should being back memories of the Creston Sonata. The designer based this design from the Selmer S-80 mouthpiece complete with square chamber.What stood out for me was the facing curve look deliberate and familiar. This means nothing until it’s printed but there are many other mouthpiece designs that have good intention but no knowledge behind them.

From first glance this piece should be quite easy to recognize. If you have play classical music in school then this rendering should being back memories of the Creston Sonata. The designer based this design from the Selmer S-80 mouthpiece complete with square chamber.What stood out for me was the facing curve look deliberate and familiar. This means nothing until it’s printed but there are many other mouthpiece designs that have good intention but no knowledge behind them.

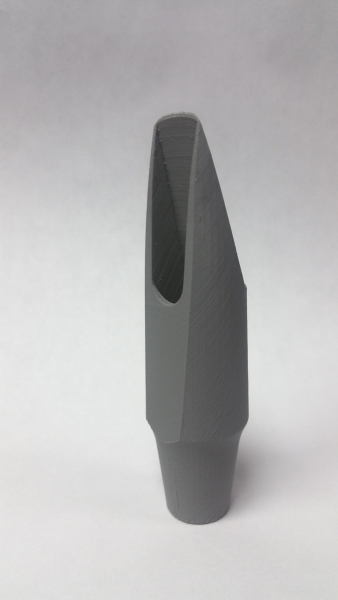

I printed the mouthpiece initially in gray PLA plastic which is generally considered safe for use in the mouth. The printer I used is my genuine Prusa I3 Mk3. This printer is considered on of the best and most advanced printers. It is tuned and produces fantastic results on everything it is tasked with printing. I printed in a low 0.3mm layer height and 20% infill. If these terms don’t make sense i’ll sum them up as layer height refers to the thickness of each layer of plastic that is stacked to make the mouthpiece. The infill refers to how much empty space there is in the walls of the model. In this case a 20% infill mean a 80% hollow interior.

Test print #1:

This piece was coarse to the touch because I printed with a really low resolution. When the mouthpiece completed printing and was removed from the plate i remove any lingering plastic detritus that stuck around and then slapped a reed on it. I chose a #3 Rico V5. I found that strength can play on almost any mouthpiece. The designers attention to detail was perfect as the mouthpiece immediately played. The tone was a bit airy as the table to reed seal had many small leaks due to the coarse layer resolution. Despite this it played and responded mostly like the S-80 should. Bolstered by this discovery I set out to print a better version and improve playablilty. The next step will be higher resolution. With high resolution come longer print times.

This piece was coarse to the touch because I printed with a really low resolution. When the mouthpiece completed printing and was removed from the plate i remove any lingering plastic detritus that stuck around and then slapped a reed on it. I chose a #3 Rico V5. I found that strength can play on almost any mouthpiece. The designers attention to detail was perfect as the mouthpiece immediately played. The tone was a bit airy as the table to reed seal had many small leaks due to the coarse layer resolution. Despite this it played and responded mostly like the S-80 should. Bolstered by this discovery I set out to print a better version and improve playablilty. The next step will be higher resolution. With high resolution come longer print times.

Test print #2:

The original print took about 6 hours to print. The predicted print time for this mouthpiece at the highest resolution the printer can make was around 14 hours. I didn’t want to wait so I choose yet another resolution a bit toward the higher resolution but not quite the finest. 8 hours later i was holding a higher res version of the same piece. This time mouthpiece sounded much better. The finer resolution meant the facing curve and table have much smaller layers visible. The meant that the airy sounds was drastically reduced. The mouthpiece was much closer to the performance of the stock hard rubber S-80. I had no issues with intonation with the piece and it was quite reed friendly. It had the warmth and slight reediness you can get from a slightly too soft reed on a S-80. Over all i was impressed and so was the sax section ahead of rehearsal that evening.

The original print took about 6 hours to print. The predicted print time for this mouthpiece at the highest resolution the printer can make was around 14 hours. I didn’t want to wait so I choose yet another resolution a bit toward the higher resolution but not quite the finest. 8 hours later i was holding a higher res version of the same piece. This time mouthpiece sounded much better. The finer resolution meant the facing curve and table have much smaller layers visible. The meant that the airy sounds was drastically reduced. The mouthpiece was much closer to the performance of the stock hard rubber S-80. I had no issues with intonation with the piece and it was quite reed friendly. It had the warmth and slight reediness you can get from a slightly too soft reed on a S-80. Over all i was impressed and so was the sax section ahead of rehearsal that evening.

Test print #3:

(FAILED)

Playability:

Believe it or not these pieces play quite well and I think with a touch up on the facing will play every bit as good as the original. The model creator did a good job modeling this mouthpiece from scratch and with only a digital calipers and ruler from an original piece.

Results:

Could this piece be printed by a band director for his bari players and save a few bucks? Sure, but the band director would need to be able to face this piece or at a minimum clean up printing artifacts. The print does present some unusual challenges but experienced 3D printer users achieve a quality output from even the most modest of printer. I recommend printing this piece using a SLA printer for the highest quality with minimal layer lines.